- +86 13869171699

- greentech@vip.163.com

Products

Products

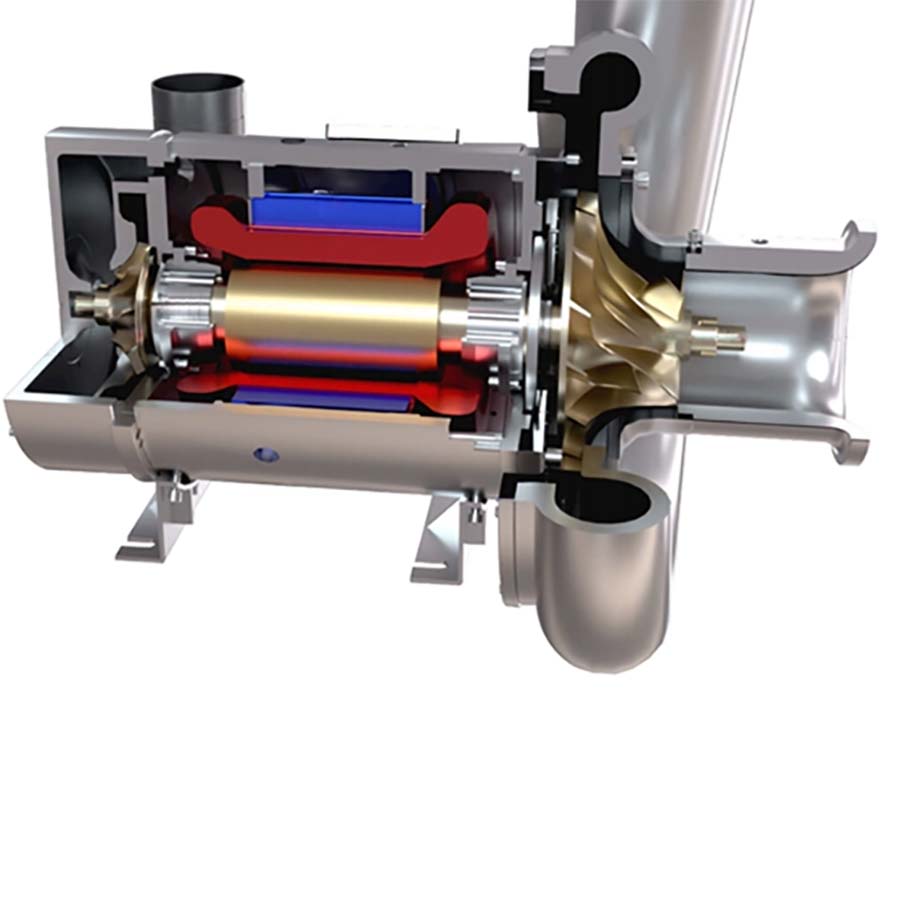

Maglev Turbo Blower

The impeller of magnetic suspension centrifugal fan is driven by direct connection between AL7075 impeller and motor. The efficiency of impeller can reach 92% and the service life of impeller can reach more than 20 years. The adjustable range of the fan can reach 45%~100%, and the working range is very wide.

Using the leading ultra-high speed permanent magnet synchronous motor technology, high-speed operation can be realized, and the efficiency of the motor can reach 97.9%. The permanent magnet synchronous motor is equipped with a speed regulating device consisting of a high-performance high-speed real-time digital controller. The system has the advantages of simple control, energy saving, stable speed and low noise. Permanent magnet synchronous motor is mainly characterized by convenient speed regulation, wide speed regulation range, stable operation, low noise and high efficiency. The speed range is large, the service life is much longer than that of traditiona

I. Core Advantage-Driven Applications

Wastewater Treatment and Environmental Engineering

Application Point: Aeration and oxygen supply (activated sludge process).

Advantage: This is the primary application area. Magnetic levitation blowers can precisely and steplessly adjust air flow in real-time based on the dissolved oxygen (DO) concentration in the biological tanks. Compared to the traditional "constant speed + valve adjustment" method of conventional blowers, this achieves energy savings of 30%-50%. The oil-free operation eliminates any risk of oil contaminating the water, and the extremely low operational noise makes them suitable for wastewater treatment plants near residential areas.

Food, Beverage, and Pharmaceutical Industries

Application Point: Fermentation aeration (e.g., yeast, amino acids, pharmaceutical fermentation), pneumatic conveying, material agitation, clean air supply.

Advantage: 100% oil-free, ensuring absolutely clean compressed air that meets stringent hygiene standards like GMP and FDA. Precise temperature and flow control provide the optimal environment for fermentation processes, enhancing product quality and consistency.

Textile and Chemical Fiber Industry

Application Point: Air-jet spinning, loom pneumatic systems, fiber conveying.

Advantage: Provides a stable, clean, and dry air supply (typically combined with an aftercooler), preventing oil stains on high-grade fabrics which can cause defects. High reliability and low maintenance requirements ensure the needs of continuous production are met.

Photovoltaic and Electronics Industry

Application Point: Material conveying and process gas circulation in polysilicon and monocrystalline silicon production.

Advantage: In high-value, extremely continuous processes like silicon production, the ultra-high reliability and zero contamination features of magnetic levitation blowers are crucial. Their intelligent early warning systems also effectively prevent significant losses from unexpected downtime.

Cement, Fly Ash, and Other Powder Conveying

Application Point: Pneumatic conveying systems.

Advantage: Stable conveying, precise control, and low energy consumption. Particularly suitable for long-distance, high-volume enclosed conveying, reducing material loss and environmental pollution.

II. Specific Requirement-Driven Applications

Aquaculture

Application Point: Aeration for deep-water net pens and industrialized recirculating aquaculture systems (RAS).

Advantage: Energy savings directly reduce operating costs. Low noise is conducive to fish growth environments, and remote intelligent control facilitates large-scale farm management.

Pneumatic Conveying

Application Point: Conveying bulk materials like grains, plastic pellets, and powders.

Advantage: Flow rate can be precisely adjusted to suit different conveying conditions. The oil-free design prevents material contamination, making system operation more environmentally friendly and reliable.

Other Industrial Fields

Printing and Packaging: Require clean air sources to power equipment.

Mining and Tunneling: Mine ventilation, tunnel construction ventilation (when high requirements for reliability and energy efficiency exist).

Laboratories and Testing Equipment: Situations requiring stable, programmable air sources.

English ▼

English ▼